Catalog

The catalog of COLORTERM presents all the materials of COLORTERM, with which LLC "COLORTERM" works.

LLC "COLORTERM" can guarantee you quality and long service life.

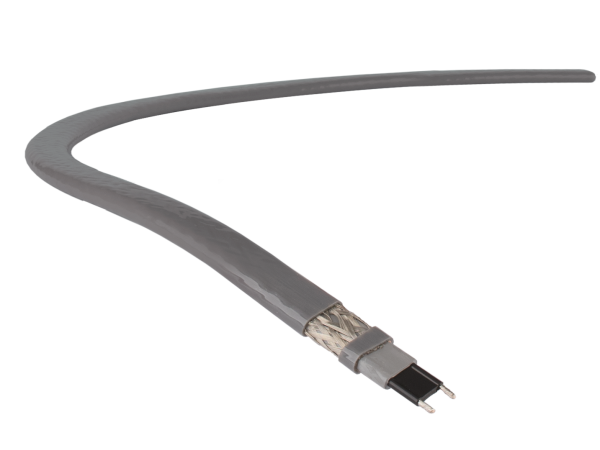

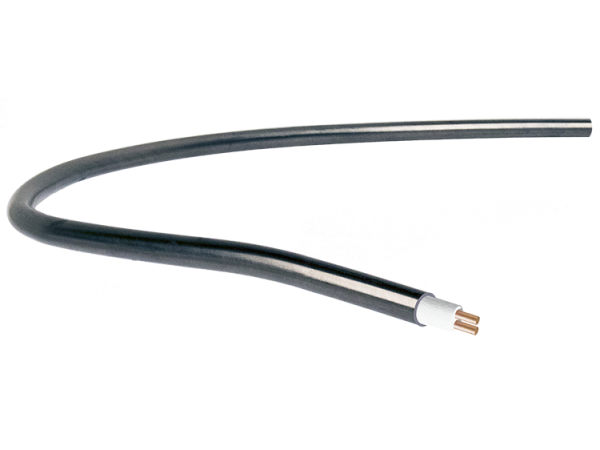

RGS self-regulating heating CABLE

Application: Protection from snow and ice.RGS self-regulating heating cables are one of the components of the SnoTrace ™ systems for protecting roofs from snow and ice produced by Thermon. Designed and approved, specially and approved for use on roofs and gutters, RGS cables are resistant to harsh environmental conditions Prevents snow and ice, protects against the destruction of roofs, gutters and pipes. Prevents the penetration of water \ pipe rupture, cracking or deformation of the gutter and dangerous snow falls from roofs. RGS self-regulating heating cables, in addition to a rigid polyolefin shell, are protected by a tinned copper braid for the purpose of grounding. These components provide maximum protection of the cable during installation and throughout the entire service life, regardless of environmental conditions.Easy to design and install:Determining the method of laying a chain using an RGS cable when using a snow and ice protection system is quite simple. Since this type of cable allows a parallel arrangement of circuits cut in length, measurements of the area of the territory where the operation of the heating system is necessary are not required.The cable can be simply pulled out of the feed bobbin, cut to the required length and installed using ordinary tools. Additional accessories for working with roofs and gutters, a set of tools will help complete the installation of the system.

More detailed

ANTI-ICING SYSTEMS OF SEA VESSELS, MOSP, SMES

In a cold marine climate, the formation of ice on ships and offshore platforms can create serious problems affecting the safety of personnel and the operation of equipment. Hair loss can be caused by sea spray and precipitation.De -icing systems were divided into two categories:Equipment or areas needed for navigation, steering, engines, anchors and rescue;Equipment or areas needed for navigation, steering, engines, anchors and rescue;Anti-icing for category 1 (Anti Icing) is defined as the prevention of ice formation, in order to keep equipment or areas free of ice at all stages of maintenance under moderate conditions (-5 0C ... -20 0C).De-icing for category 2 (Di Icing) is defined as preventing the formation of already formed ice. For such zones or equipment, de-icing measures are necessary to accumulate ice for a reasonable period of time (usually 4-6 hours) under moderate conditions (-5 0 S ... -20 0 S).Recommended capacities for anti-icing under moderate conditions (-5 0C ... -20 0C) should be at least:300 W/m2 in open areas of the deck, helicopter deck, passageways, stairs;200 W/m2 for add-ons50 W/m2 for railings with internal heatingIn conditions with lower ambient temperatures and at a higher wind speed, heat loss increases, as a result, more power is required.

More detailed

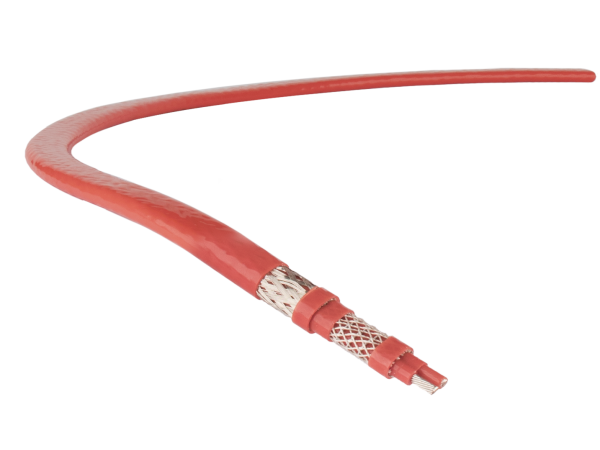

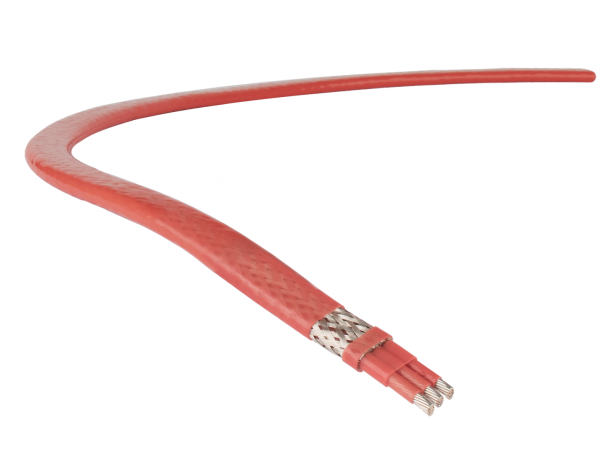

HPT POWER LIMIT CABLE

HPT's high-performance heating cables of extreme power are designed specifically to maintain process temperature and frost protection in environments where maintaining high temperatures is required. HPT cables are designed to operate in an environment with a high exposure temperature associated with steaming. The coil-doped resistor of the heating element provides a fixed heat transfer of the HPT cable. Its positive temperature coefficient reduces the output power of the cable when the temperature of the heated product increases and allows you to install the cable overlap. The composite construction of the heating element and the fibrous base in combination with an additional layer of fibrous gasket provide exceptional strength of the heating cable. HPT cables are certified for use in normal (unclassified) and potentially explosive zones according to the ATEX, TRTS and IECEx Scheme standards.Cable construction:Nickel-plated copper cores (3.3 mm2);Composite metal alloy thread;Heater bus connection (not shown);Fiberglass braid (not shown)Fluoropolymer dielectric insulationNickel-plated copper braid;Fluoropolymer shell.

More detailed

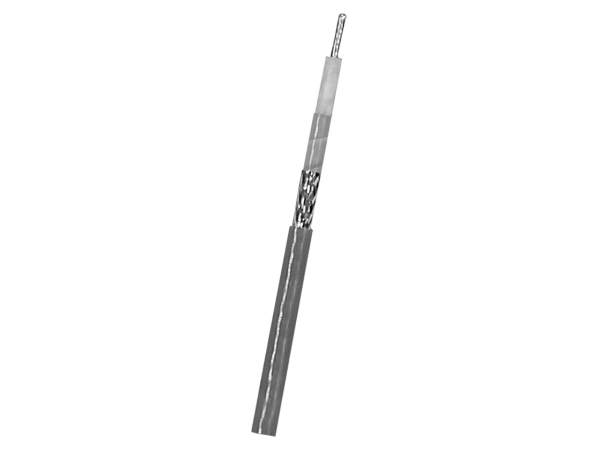

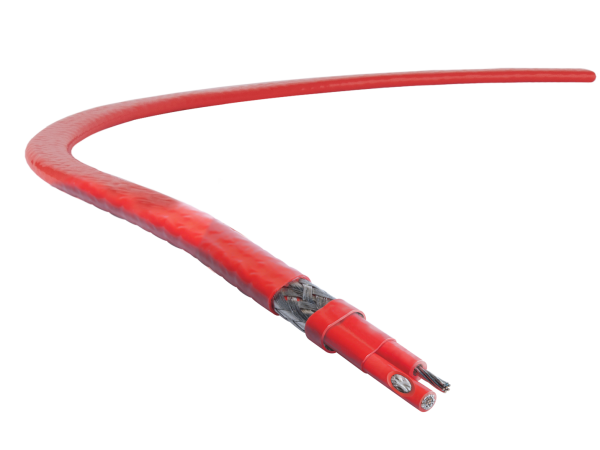

HMT LIMIT POWER CABLE

High-temperature heating cables of constant power HMT are designed specifically to protect against freezing or maintain the process temperature for working bodies in metal pipelines and tanks, where too high a temperature of maintenance and/or exposure precludes the use of heating cables with thermoplastic insulation. The parallel resistance configuration allows you to cut the cable to the desired length and terminate it directly at the installation site using easy-to-use kits supplied by "Thermon".HMT heating cables are guaranteed to provide a constant specific power output regardless of the length of the circuit. The corrugated stainless steel outer shell is an extremely robust construction designed for use in harsh operating conditions.HMT heating cables are certified for use in ordinary (unclassified) areas, as well as in explosive areas of Category 2 and 3 (Zone 1 and 2) according to the ATEX standard.

More detailed

TESH HEATING CABLE OF CONSTANT POWER

Constant power resistive heating cables of the TES series are used when the length of the circuit exceeds the limits for parallel heating cables. TESH cables are designed to work in an environment with a high exposure temperature associated with steaming. The TES series cables provide a constant output specific power over the entire length of the cable. The glass-ceramic tape additionally protects the heating cable, and the fluoropolymer shell ensures the resistance of the heating cable to chemical attack, while maintaining maximum flexibility. The cable design conforms to the EN50019 standard, "7 Joule impact test". TESH cables are designed for use in conventional (unclassified) areas and are certified according to the ATEX standard for use in explosive areas of Category 2 and 3 (Zone 1 and 2).

More detailed

MIQ HEATING CABLE OF CONSTANT POWER

Designed to maintain the process temperature or to protect against freezing, high-quality MIQ heating cables with mineral insulation are widely used to maintain high temperatures, when exposed to high temperatures and/or in installations with a high specific heat output power exceeding the limits of cables with thermoplastics insulation. The values of the electrical resistance of the cables produced make it possible to provide heating of pipelines up to 1.6 km long from one power point. Ther mon's mineral insulated MIQ cables are made of chromium-nickel alloy Alloy 825, which is ideal for use at high temperatures and provides exceptional resistance to stress corrosion in chloride, acid, salt or alkaline environments. MIG cables are designed for use in both conventional (unclassified) and explosive zones.

More detailed

TEK HEATING CABLE OF CONSTANT POWER

Temperature maintenance or frost protection of long-distance pipelinesResistive heating cables of series 1 resistance of constant power TEK are used in cases when the length of the heating circuit exceeds the limit lengths of 2 for resistive heating cables of parallel resistance.Chains up to 3,658 m long can be powered from a single point.The series resistance circuit of the TEK cable provides the same specific heat dissipation power along the entire length of the 4 cables without voltage drop.TEK cables are designed for use in both normal and explosive zones.

More detailed

HTEK HEATING CABLE OF CONSTANT POWER

Temperature maintenance or frost protection of long-distance pipelinesHigh-performance resistive heating cables of series resistance of constant power NTEK are used in cases when the length of the heating circuit exceeds the maximum lengths for resistive heating cables of parallel resistance and it is necessary to maintain or withstand the effects of high temperature.Chains up to 3,658 m long can be powered from a single point.The series resistance circuit of the TEK cable provides the same specific heat dissipation power over the entire length of the cable without voltage drop.TEK cables are designed for use in both normal and explosive zones.

More detailed

ELECTRIC HEATING BY THE THERMTRAC SKIN EFFECT METHOD

The ThermTrac system is a cost-effective alternative to standard heating systems with sequential resistance in extended pipelines, since it eliminates the need to use an extensive power distribution system. The system allows to provide electric heating of the pipeline with a length of up to 25 kilometers from just one power supply point. The operational flexibility of the system allows it to be used to maintain temperature, protect against freezing and warming up.The system generates heat in the heating tube by means of a reverse current passing through the impedance of the inner surface of the heating tube.There is no voltage and current on the outer surface of the heating tube.ThermTrac insulated core is the basis of a heating system based on the skin effect of the Thermon company. This core is developed by Thermon individually for each customer, while its dielectric insulation and abrasion-resistant shell meet the conditions of specific customer projects. Copper cores with polyolefin insulation can be used for projects to protect against freezing and maintain low temperatures. Fluoropolymer insulated cores provide excellent temperature performance, operational flexibility and durability required for high temperature systems.

More detailed

PRE-INSULATED HEATED PULSE TUBES FOR INSTRUMENTATION

The ThermTrac system is an economical alternative to standard heating systems with sequential resistance in extended pipelines, since it eliminates the need for an extensive power distribution system. The system allows to provide electric heating of the pipeline with a length of up to 25 kilometers from just one power supply point.The operational flexibility of the system allows it to be used to maintain temperature, protect against freezing and warming up.The system generates heat in the heating pipe by means of a reverse current passing through the resistance of the inner surface of the heating pipe.There is no voltage and current on the outer surface of the heating tube.ThermTrac insulated core is the basis of a heating system based on the Thermon skin effect. This core is developed by Thermon individually for each customer, and its dielectric insulation and wear-resistant shell meet the conditions of specific customer projects. Copper cores with polyolefin insulation can be used in projects to protect against freezing and maintain low temperatures. Fluoropolymer insulated cores provide excellent temperature characteristics, operational flexibility and durability required for high temperature systems.

More detailed

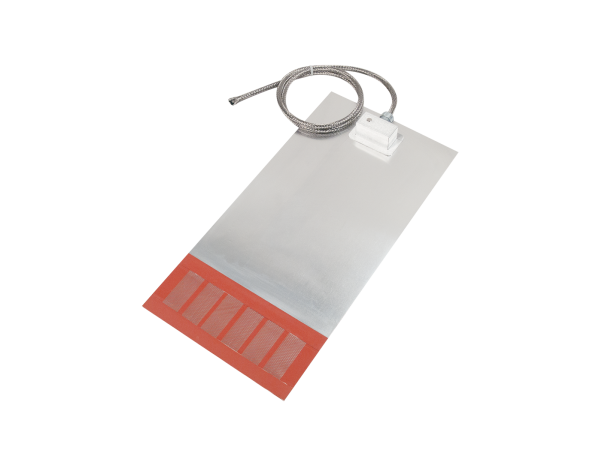

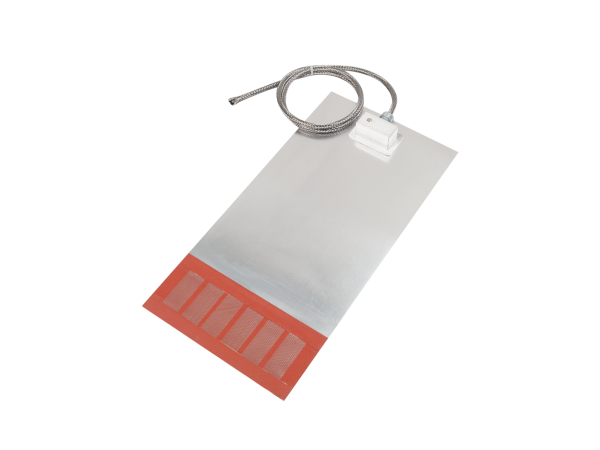

ELECTRIC HEATING OF TANKS WITH RT PANELS

RT FlexiPanel is an independent, high-performance and flexible heating panel designed specifically for use in metal tanks and containers.The RT FlexiPanel panel provides a power output of 2 watts per square inch (3,100 watts per square meter) and distributes heat evenly over the entire surface of the panel. 1 The low profile flexible design of the panel ensures its quick and easy installation using the mounting kit purchased from Thermon. In order to provide a large number of paths for the passage of electric current, the RT FlexiPanel panel uses a parallel circuit based on a stamped high-temperature heating element made of alloy. This design eliminates the risk of module burnout, which is typical for heating modules with sequential circuits. The robust design of the RT FlexiPanel panel includes a rigid metal shell that provides mechanical protection during delivery and installation of the panel. In addition, the heating element of the panel is protected from vibrations and moisture by placing it in a thermally laminated layer of organosilicon rubber, which serves as a sealing gasket and a waterproof seal.FEATURESHeating of tanks and containersSpecially designed for metal tanks and containersUniform heat distributionCertified for use in normal (not classified in any category) areas and in potentially explosive environments

More detailed

ELECTRIC HEATING OF TANKS WITH RTF PANELS

RTF FlexiPanel is an independent, high-performance and flexible heating panel designed specifically for use in fiberglass and plastic tanks and containers and in metal tanks and containers containing high viscosity liquids and liquids sensitive to temperature changes. The RTF FlexiPanel panel provides an output power of 1,085 watts per square meter (0.7 watts per square inch) or less and distributes heat evenly over the entire surface of the panel to ensure a stable temperature.1 The low profile flexible design of the panel ensures its quick and easy installation using the mounting kit purchased from Thermon. In order to provide a large number of paths for the passage of electric current, the RTF FlexiPanel panel uses a parallel circuit based on a stamped high-temperature heating element made of alloy. This design eliminates the risk of module burnout, which is typical for heating modules with sequential circuits. The robust design of the RTF FlexiPanel panel includes a rigid metal shell that provides mechanical protection during delivery and installation of the panel. In addition, the heating element of the panel is protected from vibrations and moisture by placing it in a thermally laminated layer of organosilicon rubber, which serves as a sealing gasket and a waterproof seal.FEATURESHeating of tanks and containersSpecially designed for fiberglass and plastic tanks and containersUniform heat distributionCertified for use in normal (not classified in any category) areas and in potentially explosive environments

More detailed