Catalog

The catalog of COLORTERM presents all the materials of COLORTERM, with which LLC "COLORTERM" works.

LLC "COLORTERM" can guarantee you quality and long service life.

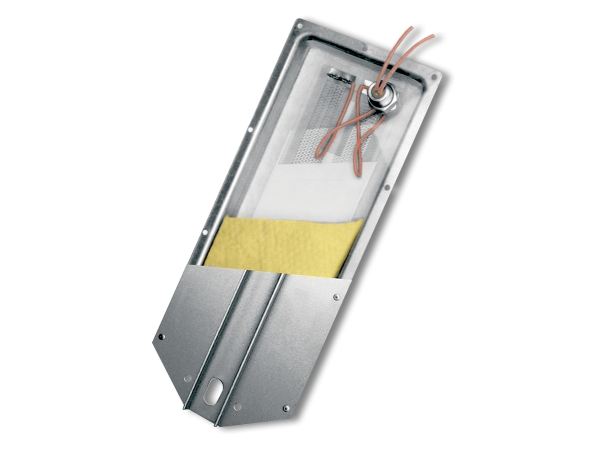

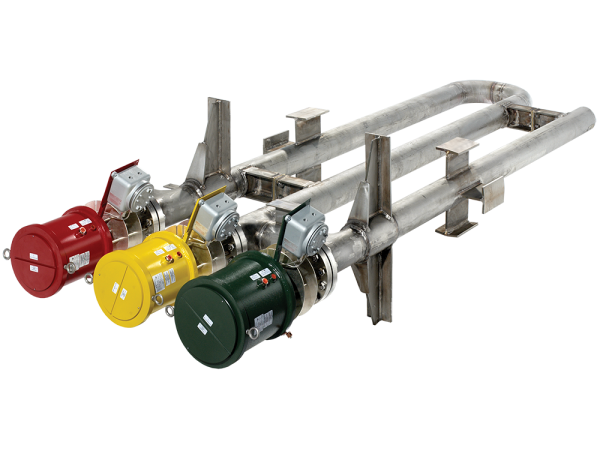

ELECTRIC HEATING OF TANKS BUNKERS AND GUTTERS HT

The HT hopper heating module is a robust, reliable and high-performance heater enclosed in a robust housing, designed to work on surfaces subject to vibration. Designed to provide thermal power up to 4650 W/m2, the HT module distributes heat evenly over the entire surface of the panel. To ensure optimal performance, each system is designed by Thermon specialists based on specific thermal requirements. The use of parallel circuits based on a stamped INCONEL ® high-temperature heating element ensures that the HT heating module has many paths of flowing electric current. This design eliminates the possibility of burnout, which is common for sequential circuits using wire. The protection of the heating element from vibration is provided by an elastic gasket made of insulating material, which also directs the heat flow from the module to the heated surface. The HT tank heating module is certified for use in normal (unclassified) and explosive zones.

More detailed

SEALS WITH INDICATOR LAMP ZP-XP, ZP, ZL, ZS|ZP

Non-metallic terminal sealing kits for Terminator heating cables are specially designed for quick and easy installation of Thermon heating cables. The complex design of these non-metallic kits combines in one set a mounting column for installation on a pipeline, an insulating sleeve of a heating cable and a cable deformation compensation system. To make it easier to install the kit cover and at the same time increase its safety, the kit cover is fixed without using screws (to remove the cover after installing the kit, you will need a special tool). Terminator kits can be used in normal (non-classified) zones, and they are also certified in accordance with the ATEX directive, which provides for their use in zones classified in categories 2 and 3 (zone 1 and 2). ETK circuit assembly kits should be used with all sets for connecting parallel resistance heating cables manufactured by Thermon. The SX cable termination kit includes a connecting sleeve, a plug, cold-curing glue and a signal sticker. The kits for the end sealing of HPT and FP cables also include a piece of tape and an insulating sleeve. The SCTK splice and end sealing kits should be used when performing splice from the outside of the insulation using any kit for connecting parallel resistance heating cables manufactured by Thermon. The SX cable end sealing kit includes 2 splice sleeves, couplings for splicing wires of various types and cold-curing glue. The kits for the end sealing of HPT and FP cables also include an insulating sleeve.

More detailed

POWER CONNECTION BOXES ZP-M-XP(WP) FOR TEK AND HTEK CABLES

Terminator Beacon circuit serviceability indicator kits are specially designed for quick and easy installation of Thermon self-regulating heating cables of parallel resistance of maximum power with polymer insulation manufactured by Thermon. The complex design of these non-metallic kits combines in one set a mounting column for installation on a pipeline, an insulating sleeve of a heating cable and a cable deformation compensation system with a voltage indicator at the end of the circuit. To make it easier to install the kits, the use of mounting screws is not required during their installation. The Terminator Beacon kit is equipped with a green LED indicator lamp of increased brightness, which is clearly visible both during the day and at night. This kit can also be equipped with a red LED indicator lamp of increased brightness. The domed lens allows you to see the indicator well from a great height. Terminator Beacon kits can be used in normal (not categorized) zones, and they are also certified in accordance with the ATEX directive, which provides for their use in zones classified in categories 2 and 3 (zone 1 and 2).

More detailed

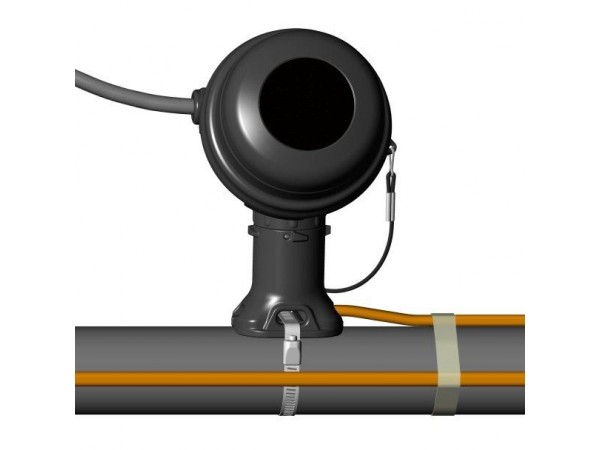

END SEAL EQUIPPED WITH ZEB LEDS

Terminator Beacon circuit serviceability indicator kits are specially designed for quick and easy installation of Thermon self-regulating heating cables of parallel resistance of maximum power with polymer insulation manufactured by Thermon. The complex design of these non-metallic kits combines in one set a mounting column for installation on a pipeline, an insulating sleeve of a heating cable and a cable deformation compensation system with a voltage indicator at the end of the circuit. To make it easier to install the kits, the use of mounting screws is not required during their installation. The Terminator Beacon kit is equipped with a green LED indicator lamp of increased brightness, which is clearly visible both during the day and at night. This kit can also be equipped with a red LED indicator lamp of increased brightness. The domed lens allows you to see the indicator well from a great height. Terminator Beacon kits can be used in normal (not categorized) zones, and they are also certified in accordance with the ATEX directive, which provides for their use in zones classified in categories 2 and 3 (zone 1 and 2).

More detailed

TERMINATOR ZP-PTD-100 JUNCTION BOX FOR TEMPERATURE SENSOR

Terminator ZP-PTD100-WP 4 mm2 1M 25/3M 20 (Std.) - connecting non-metallic box, IP66, for PTD-100 sensor, with wall mounting kit.Scope of applicationHeating of pipelines;Tank heating;Heating of equipment.

More detailed

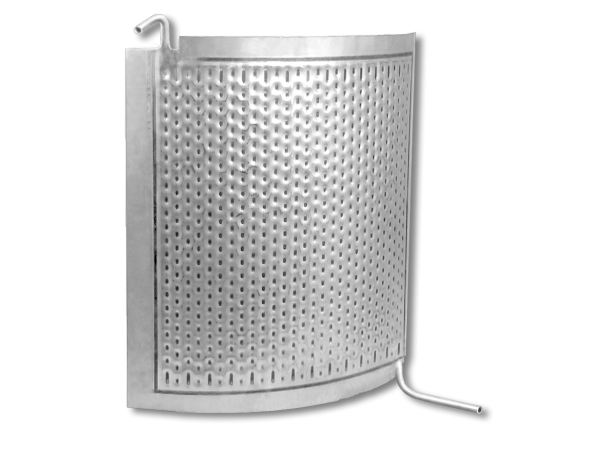

STEAM HEATING

Heating modules for heating HeetSheet tanks are made of 304 stainless steel of caliber 26 in accordance with the requirements of the ASTM A240 standard. The welded cellular structure provides numerous fluid flow paths, which reduces the risk of congestion typical of single-channel structures.For operation at temperatures up to 190 °C, a non-hardening heat-conducting mixture is applied to the surface of the HeetSheet module by the factory method, which is in contact with the tank wall. This is done to eliminate air and ensure good thermal contact.Heetsheets are available in different sizes and are folded in such a way as to match the radius of the tank. Stainless steel connecting tubes are provided for the supply of steam and other heating or cooling media. Fittings that are not included in the standard delivery package are used to connect the inlet and outlet pipes to the pre-insulated ThermoTube medium supply and outlet pipeline. The tubes of the Thermotube are supplied separately.AdvantagesEach design is based on known and predicted heat transfer coefficients.Thermon heat-conducting mixtures provide a high heat transfer rate.The area of the heating panel should be only from 1/2 to 1/3 of the surface area of the heated tank.Pre-rolled modules guarantee speed and ease of installation.The modules can be used for both heating and cooling.Cross-contamination of the heating medium and the contents of the tank/container is not possible.

More detailed

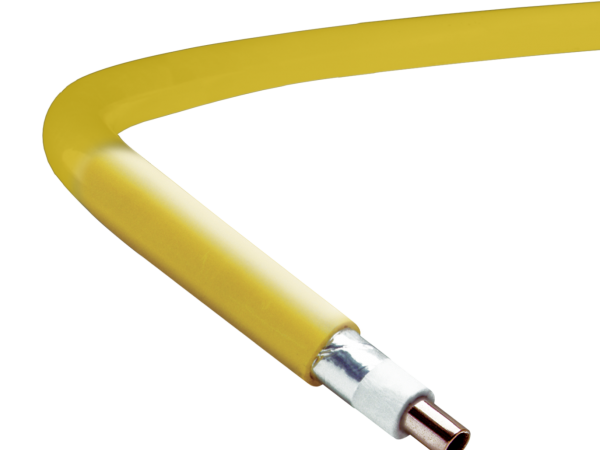

SAFETRACE STEAM TRACING

The SafeTrace DLS-IT steam tracing is a metal heating tube coated with composite materials, which are used to reduce thermal conductivity. The SafeTrace steam tracing provides predicted thermal output power along the entire length of the heated pipe in order to prevent overheated sections and overheating of the entire pipe. The steam tracing replaces non-insulated metal traces, the use of which often leads to unproductive energy costs and excessive pipeline stress, since when they are used, the temperature of the pipes goes beyond the required or desired parameters. SafeTrace DLS-IT steam tracing have a yellow protective identification sheath, warning of the presence of potentially hazardous materials, such as steam, in accordance with the requirements of the ASME/ANSI A13.1-1996 standard. All SafeTrace IT traces also comply with the requirements of the ASTM Std C-1055 standard, according to which the human skin temperature should not exceed 58 °C for five seconds when in contact with hot surfaces. The SafeTrace DLS-IT steam tracing is delivered in long bays. It can be stretched continuously from the collector of the steam supply system along the pipe to the condensate drain collector.

More detailed

PRE-INSULATED THERMOTUBE TUBES

ThermoTube pre-insulated tubes are single-layer insulated tubes that are ideal for transporting hot and cold liquids and gases. These tubes have been designed specifically for steam supply and condensate drainage lines. In addition, these tubes are used for the organization of unheated sampling lines.The preliminary insulation of the ThermoTube tube consists of non-hygroscopic fiberglass, heat-reflecting foil and an outer shell to protect against the effects of adverse weather conditions. ThermoTube working tubes can be made of many different materials with walls of different thicknesses and different outer shells.FEATURESFast delivery and installationLong bays minimize wasteExcellent protection against adverse weather conditions

More detailed

EXPLOSION-PROOF ELECTRIC HEATERS

The explosion-proof FE2 electric air heaters are designed for the harshest operating conditions. Designed for use in industrial premises in hazardous areas where explosive gases or dust may be present.It uses the VacuCore liquid heat exchanger, which provides high efficiency, fast heating and uniform heat distribution from the front side of the heat exchanger.It is also possible to apply a Heresite coating and use a stainless steel construction for environments with a high level of corrosion.The power range of the models is 2.5 - 35 kW, the voltage range is 220-480 V.Comply with CE/ATEX II 2 G, Ex d IIB T3 Gb standards and EAC specifications for the global market.EAC certification for operation at -50°C.It is possible to install a thermostat and a built-in circuit breaker.

More detailed

SUBMERSIBLE HEATERS

Heaters inserted into pipes - MX series

Designed for uniform distribution of heat across storage tanks for high viscosity liquids such as asphalt, molasses, resin, paint, glue, wax and oil, without causing burning or coking of these liquids.The standard voltage range is from 208 to 660 V. The device can be equipped with a NEMA 4 enclosure for outdoor use or an explosion-proof terminal housing for use in hazardous areas. Standard heaters use heavy-duty elements with an alloy shell with flanges with a diameter of 3" (150 pounds) or threaded plugs of the NPT standard with a diameter of 2" with moisture-resistant terminal housings. Additional functions: prefabricated control systems, individual power or voltage, built-in thermostats, increased limit values and explosion-proof enclosures. TRTS certified.

Flange heaters — CX seriesSubmersible heaters are mainly used for process heating in explosive and safe areas, for example, in pressure vessels and in pipe assembliesTechnological media can be water, heavy and light hydrocarbons, acids, polymers, salts and gases, depending on the length of the element, are produced with a power of 500 W - 2.5 MW with a supply voltage 120, 208, 220, 380, 400, 415, 600, 660, 690 V.

Screw-in heaters - CX seriesDesigned for heating systems of water, oil, gas and mildly aggressive liquids, standard devices include threaded plugs with a diameter from 1" to 2.5". Heaters can be made of copper, Incoloy ® and Inconel ® materials, nickel-plated steel and other metal materials. Additionally, the devices can be equipped with a thermostat. Individually designed heaters can have any voltage, up to 660 V. The shell and plug of such heaters can be made of special materials. Heaters can have universal, moisture-resistant and explosion-proof terminal housings. The devices comply with the requirements of Chapters 1 and 2 of the API Bulletin 614 Certified by EAC

Submersible heaters attached to the edge of the surface - DX, HX, QM seriesDesigned for liquid heating systems. The standard voltage range is from 208 to 660 V. The power range is from 3 to 7.5 kW for heaters with one element and from 9 to 22.5 kW for devices with three elements. The shell can be made of copper, Incoloy ® and Inconel ® materials, nickel-plated steel and other metal materials. The coupling can be made of Tefl ® material or quartz. Certified by CSA.

More detailed

SPECIALIZED AND CIRCULATING HEATERS

Plate heaters - FS, SD, SS seriesDesigned for use in various heating systems, including surface heating systems, working air heating systems, lowering resistors for pipelines on railways and load batteries, frost protection systems and many others. They can be equipped with fins to increase heat transfer to the air. Made of high-quality materials, including high-resistance heat-resistant alloy wire and corrosion-resistant aluminum-coated steel shell (maximum shell temperature is 1000°F / 538°C) or corrosion-resistant stainless steel shell (maximum shell temperature is 1200 °F/ 649°C). Certified by EAC

Circulation heaters - EX series.Provide linear electric heating in heating systems with forced circulation. The power of the heaters ranges from 0.6 to 5000 kW. Heaters of higher power can also be manufactured. The products can be additionally equipped with thermostats, welded stainless steel parts and moisture-proof or explosion-proof housings. Increased performance limits may also be provided for them. Containers and heaters are registered in the CRN registry for use in Canada. Devices are allowed to be marked U, U2 and N, depending on the classification of ASME codes (Section VIII or III). Certified by TR CU.

More detailed

AIR AND ROOM HEATERS

Heating units with forced air supply - GE series

Designed for use in conventional heating systems for industrial and commercial premises. Case with phosphate epoxy coating made of 18-gague thick steel. Additional equipment installed at the factory in accordance with the customer's requirements, including thermostats, controls and a wall mounting bracket. 35 models, the power range of which is from 2 to 40 kW, and the voltage range is from 208 to 600 V. EAC certified.

More detailed