The catalog of COLORTERM presents all the materials of COLORTERM, with which LLC "COLORTERM" works.

LLC "COLORTERM" can guarantee you quality and long service life.

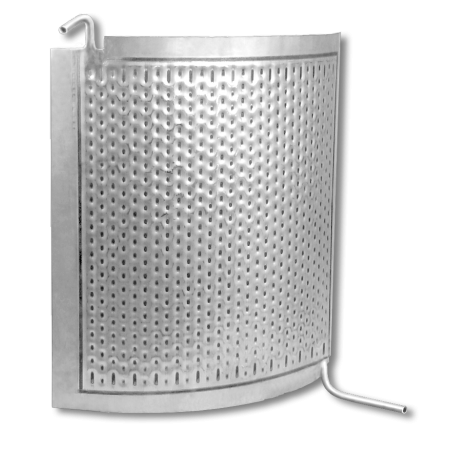

STEAM HEATING

Heating modules for heating HeetSheet tanks are made of 304 stainless steel of caliber 26 in accordance with the requirements of the ASTM A240 standard. The welded cellular structure provides numerous fluid flow paths, which reduces the risk of congestion typical of single-channel structures.

For operation at temperatures up to 190 °C, a non-hardening heat-conducting mixture is applied to the surface of the HeetSheet module by the factory method, which is in contact with the tank wall. This is done to eliminate air and ensure good thermal contact.

Heetsheets are available in different sizes and are folded in such a way as to match the radius of the tank. Stainless steel connecting tubes are provided for the supply of steam and other heating or cooling media. Fittings that are not included in the standard delivery package are used to connect the inlet and outlet pipes to the pre-insulated ThermoTube medium supply and outlet pipeline. The tubes of the Thermotube are supplied separately.

Advantages

- Each design is based on known and predicted heat transfer coefficients.

- Thermon heat-conducting mixtures provide a high heat transfer rate.

- The area of the heating panel should be only from 1/2 to 1/3 of the surface area of the heated tank.

- Pre-rolled modules guarantee speed and ease of installation.

- The modules can be used for both heating and cooling.

- Cross-contamination of the heating medium and the contents of the tank/container is not possible.

Technical specifications

- Maximum operating temperature 190 °C

- Minimum operating temperature -196 °C

- Maximum working pressure 1,136 kPa

- Maximum field test pressure 1,700 kPa

- Heat transfer coefficient 1 from the HeetSheet module to the tank wall

Construction

- Steel tubes with an outer diameter of 3/8” for connection of inlet and outlet pipelines

- 304 Stainless Steel Mesh Panel

- Factory-applied non-hardening heat-conducting

Certificates / Permissions

ASME does not require mandatory certification of modules of small internal volume and pressure. In particular, the maximum energy that the HeetSheet panel can store is noticeably lower than the limit values established by the Certification Code and corresponding to the pressure values presented below:

- 0.14 m3 and 1720 kPa

- 0.08 m3 and 2410 kPa

- 0.08 m3 and 2410 kPa

HeetSheet modules are designed and manufactured in accordance with the requirements of Section VIII of Part 1 of the ASME standard "Rules for Boiler Installations and Pressure Vessels", but are not checked and marked accordingly.2