The catalog of COLORTERM presents all the materials of COLORTERM, with which LLC "COLORTERM" works.

LLC "COLORTERM" can guarantee you quality and long service life.

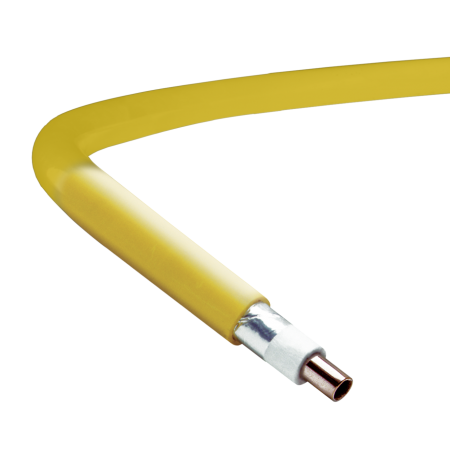

SAFETRACE STEAM TRACING

The SafeTrace DLS-IT steam tracing is a metal heating tube coated with composite materials, which are used to reduce thermal conductivity. The SafeTrace steam tracing provides predicted thermal output power along the entire length of the heated pipe in order to prevent overheated sections and overheating of the entire pipe. The steam tracing replaces non-insulated metal traces, the use of which often leads to unproductive energy costs and excessive pipeline stress, since when they are used, the temperature of the pipes goes beyond the required or desired parameters. SafeTrace DLS-IT steam tracing have a yellow protective identification sheath, warning of the presence of potentially hazardous materials, such as steam, in accordance with the requirements of the ASME/ANSI A13.1-1996 standard. All SafeTrace IT traces also comply with the requirements of the ASTM Std C-1055 standard, according to which the human skin temperature should not exceed 58 °C for five seconds when in contact with hot surfaces. The SafeTrace DLS-IT steam tracing is delivered in long bays. It can be stretched continuously from the collector of the steam supply system along the pipe to the condensate drain collector.

Technical specifications

- Available tube diameters are 3/8” and 10 mm

- Nominal outer diameter of 25 mm

- Materials from which the tube is made copper and stainless steel

- Typical pipe temperature range 5 °C - 54 °C

- Maximum exposure temperature 215 °C

- Minimum installation temperature -40 °C

- The maximum recommended steam pressure is 1825 kPa

- Typical maximum shell temperature <58 °C3

Construction

- Copper or stainless steel tube

- Heat insulator

- Heat-reflecting tape

- Yellow protective polymer shell